Call: 08045814943

Pinion Seal

Price 70 INR/ Piece

MOQ : 1 Piece

Pinion Seal Specification

- Product Type

- Pinion Seal

- General Use

- Sealing pinion shaft in automotive and industrial machinery

- Material

- Rubber (Nitrile or Viton) with Metal Reinforcement

- Type

- Rotary shaft seal

- Moving Type

- Fixed/Non-moving

- Speed

- Suitable for moderate to high rotary speeds

- Weight (kg)

- Approx. 0.05 kg (varies by size)

- Computerized

- No

- Automatic

- No

- Hydraulic Steering

- No

- Dimension (L*W*H)

- Dependent on application (typ. OD 40-100 mm)

- Feature

- Leak-proof, durable, resistant to oil and abrasion

- Color

- Black

- Application

- Used in differential, transmission, and pinion gear assemblies

- Temperature Range

- -40°C to +120°C

- Shape

- Circular

- Surface Finish

- Precision molded rubber with metal

Pinion Seal Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 2-3 Days

About Pinion Seal

Get spectacular savings on our Top-grade Pinion Seal, expertly engineered for majestic performance in differential, transmission, and pinion gear assemblies. This rotary shaft seal features a circular shape and is manufactured using unparalleled precision-molded nitrile or Viton rubber reinforced with metal for exceptional resilience. With a wide temperature range from -40C to +120C and outstanding oil and abrasion resistance, it ensures leak-proof sealing in automotive and industrial machinery. Perfect for moderate to high rotary speeds, our durable offering is available from a leading manufacturer, exporter, and wholesaler in India.

Pinion Seal: Usage, Applications & Competitive Edge

Pinion Seals are vital for sealing pinion shafts in automotive transmissions and industrial machinery, providing unmatched protection against leaks. Their robust construction and precision surface finish ensure lasting durability, even under high rotary speeds. Application sites include differentials, power transmission systems, and gear assemblies. Competitive advantages include enhanced oil resistance, exceptional leak-proofing, and superior abrasion durability, all at top market prices, making these seals ideal for both automotive and industrial players seeking reliable solutions.

Pinion Seal Sample Policy, Certifications & Shipping

We offer a convenient sample policy to help you evaluate the product's fit for your specific needs. Certified for quality and performance, our Pinion Seals come securely packaged to prevent damage during transit. Benefit from express shipping, ensuring timely delivery right to your preferred FOB port in India. Whether you require bulk or trial orders, our experienced export team supports you from packaging to documentation, ensuring a seamless procurement experience for clients worldwide.

Pinion Seal: Usage, Applications & Competitive Edge

Pinion Seals are vital for sealing pinion shafts in automotive transmissions and industrial machinery, providing unmatched protection against leaks. Their robust construction and precision surface finish ensure lasting durability, even under high rotary speeds. Application sites include differentials, power transmission systems, and gear assemblies. Competitive advantages include enhanced oil resistance, exceptional leak-proofing, and superior abrasion durability, all at top market prices, making these seals ideal for both automotive and industrial players seeking reliable solutions.

Pinion Seal Sample Policy, Certifications & Shipping

We offer a convenient sample policy to help you evaluate the product's fit for your specific needs. Certified for quality and performance, our Pinion Seals come securely packaged to prevent damage during transit. Benefit from express shipping, ensuring timely delivery right to your preferred FOB port in India. Whether you require bulk or trial orders, our experienced export team supports you from packaging to documentation, ensuring a seamless procurement experience for clients worldwide.

FAQ's of Pinion Seal:

Q: How does a Pinion Seal enhance the performance of my gear assemblies?

A: A Pinion Seal provides a leak-proof and durable barrier, preventing oil and contaminants from escaping or entering differential, transmission, and pinion gear assemblies, thus extending the life and reliability of these crucial automotive and industrial components.Q: What is the typical usage process for installing a Pinion Seal?

A: The Pinion Seal is fixed into the housing around a rotating pinion shaft. Ensure the shaft surface is smooth and clean before pressing the seal in place using installation tools designed for rotary shaft seals.Q: When should I consider replacing a Pinion Seal in machinery?

A: It is advisable to replace the Pinion Seal once you observe any oil leakage, abnormal noises, or contamination in the differential or transmission assembly, ensuring optimal machine operation and reducing risks of severe component wear.Q: Where are Pinion Seals most commonly used?

A: Pinion Seals are most commonly utilized in automotive gearboxes, differentials, power transmissions, and a variety of industrial machinery requiring effective rotary shaft sealing.Q: What certifications do your Pinion Seals offer for quality assurance?

A: Our Pinion Seals are manufactured under rigorous quality control and are certified for oil resistance, durability, and leak-proof performance to guarantee client satisfaction and meet industry standards.Q: How can express shipping benefit my procurement process for Pinion Seals?

A: Express shipping enables prompt delivery, ensuring your maintenance schedule or production timeline proceeds without delays. Our robust packaging further safeguards seals during transit to your FOB port.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in JCB Parts Category

Window Handle Left Hand

Price 150 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Casement Window Handle

General Use : Window Frame Operating

Material : Other, Aluminum alloy

Product Type : Window Handle Left Hand

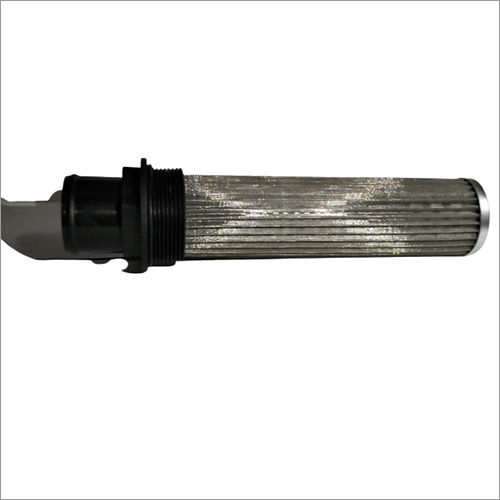

Hydraulic Stainer Filter

Price 250 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Return Line Filter

General Use : Filtration of hydraulic fluids

Material : Stainless Steel

Product Type : Hydraulic Stainer Filter

KING PIN REPAIR KIT

Price 450.0 INR / Unit

Minimum Order Quantity : 5 Units

Type : REPAIR KIT

General Use : JCB parts

Material : Stainless Steel

Product Type : KING PIN REPAIR KIT

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry